Recovery of Phosphorus from Municipal Wastewater using Alumina Nanoparticles

1.0 Introduction

Phosphorus plays an essential role in the agricultural sector as they are used as fertilizer or feed. There has been a drastic demand for phosphorus due to population growth and changes in eating habits. The world’s ability to provide enough food to feed the growing population is dependent on fertilizer application. The major source of phosphorus fertilizer is phosphate rock. Statistics from our world in data reveal that as of 2017 the world’s phosphate fertilizer production was 55.79 million tonnes. These phosphate-rich rocks are situated at very limited places including Morocco, United States, China, etc as depicted in figure 1.

Countries lacking Phosphorus deposits are entirely dependent on imports and are therefore vulnerable to market fluctuations in fertilizer and mineral Phosphorus prices (World Bank, 2016). One of many measures for reducing dependency is the recovery of Phosphorus from obviously available but currently often unexploited national Phosphorus sources such as municipal and industrial wastewater, meat and bonemeal (MBM) and other organic wastes (Scholz et al., 2014).

Biological and chemical precipitation methods are mostly employed for the removal of Phosphorus from the wastewater streams. However the use of these methods are mostly used for streams with high concentrations of Phosphorus.

2.0 Solutions

2.1 Production of alumina nanoparticles

Aluminium foil waste is valorised into Aluminium chloride and polyphenols specifically tannins are extracted from depulped coffee cherries. The two chemicals are then reacted to produce alumina nanoparticles which are then placed in an adsorption column. These nanoparticles have high affinity for the precipitation of Phosphorus from municipal wastewater.

2.2 Design of adsorption column

The adsorption column is designed to remove phosphorus from municipal wastewater effluents. The system involves a column packed with highly porous alumina and works by reducing phosphorus levels from a digester having high concentration through adsorption and chemical precipitation achieving phosphorus levels as low as 1mg/l.

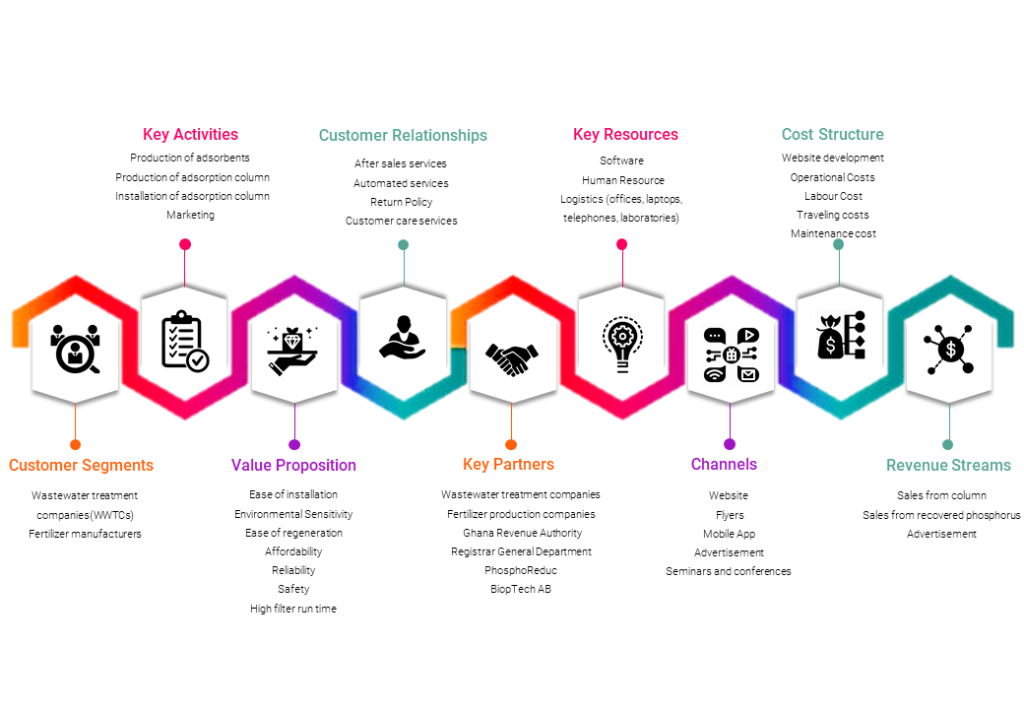

3.0 Business Model

3.1 VALUE PROPOSITIONS

Regarding all other column manufacturers, the following are the main reasons our customer segments would like to do business with us;

• Ease of installation: Our columns are easy to install for the retrieval of phosphorus in wastewater. It does not require any superior skills to do the installation. Other customers who are unable to install the column on their own will have trained people from our team who will install the column for them.

• Environmental sensitivity: Green route will be adopted to produce our adsorbent which little or no CO2 emissions. This will help to reduce climate change. Moreover, the abandoned aluminium foil left at the landfill to will be valorised and this solves the issues of producing undesirable liquid leachate, heat, and gases, for example carbon monoxide, ammonia, hydrogen sulphide, and hydrogen.

• Ease of regeneration: The adsorbent could be regenerated more than once it has a longer ripening time.

• Affordability: Our product is very affordable comparing it to other products. In as much as affordability is relative, the high function-ability of our column compared to the effectiveness and efficiency is what amounts to this affordability.

• Reliable: Our product is reliable; they are able to perform their functions in different environments i.e., whether in Ghana here or outside of Ghana.

• Safety: Products such as aluminium foil and the coffee extracts (Polyphenols) are not dangerous. The materials used as precursors for the synthesis of the adsorbent will not have adverse effect on the plants and humans’ health.

• High filter run time: Unlike other columns, our manufactured columns are not easily clogged by contaminates which come from the wastewater. It can be easily cleaned and installed back into the column to work normally.

3.2 Revenue Stream

Most of the revenues shall be from the sales of the adsorption column with the alumina nanoparticles.

4.0 Expected Outcome

It is expected that;

- locally and readily available waste would be utilized to produce adsorbent.

- green route would have been adopted to synthesize alumina with high affinity for phosphate removal.

- the designed adsorption column would have the desired capabilities to reduce the WWTP’s effluent quality to the acceptable EPA effluent discharge.

Our Team

BSC. Natural Resource Management MSC. Water Supply and Environ. BSC. Architecture

KNUST,Kumasi-Ghana KNUST,Kumasi-Ghana KNUST,Kumasi-Ghana

References

Bayus, J., Ge, C., & Thorn, B. (2016). “A preliminary environmental assessment of foil and metallized film centered laminates. Resources Conservation and Recycling, 115, 31–41.

L. Bashan, Y. Bashan, Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997–2003), Water Res. 38 (2004) 4222–4246.

Buryakovskaya, O. ., Meshkov, E. ., Vlaskin, M. ., Shkolnokov, E. ., & Zhuk, A. . (2017). Utilization of Aluminum Waste with Hydrogen and Heat Generation. Materials Science and Engineering, 012007, 250.

Calder, G. V., & Stark, T. D. (n.d.). Aluminum Reactions and Problems in Municipal Solid Waste Landfills. Practice Periodical of Hazardous, Toxic, and Radioactive Waste Management, 14(4), 2010.

George, T, & Franklin, L. (1991). Wastewater Engineering. Metcalf & Eddy, Inc.,. 691.

Ghotekar, S. (2019). Plant extract mediated biosynthesis of Al 2 O 3 nanoparticles- a review on plant parts involved , characterization and applications. 4(2), 163–169. https://doi.org/10.22036/ncr.2019.02.008

Scholz, R. W., Roy, A. H., & Hellums, D. T. (2014). Sustainable phosphorus management: A global transdisciplinary challenge. 1–113.

World Bank. (2016). World Bank GEMcommodities databank for phosphate rock. DAP, TSP, Urea and Pottasium Chloride. http://data.worldbank.org/data-catalog/commodityprice-%0Adata.

W.W. Huang, S.S. Wang, Z.Z. Zhu, L.L. Li, X.X. Yao, V.V. Rudolph, F. Haghsereshta, Phosphate removal from wastewater using red mud, J. Hazard. Mater. 158 (2008) 35–42.