BG+, the solution for your pollution

What’s going on in Daegu City?

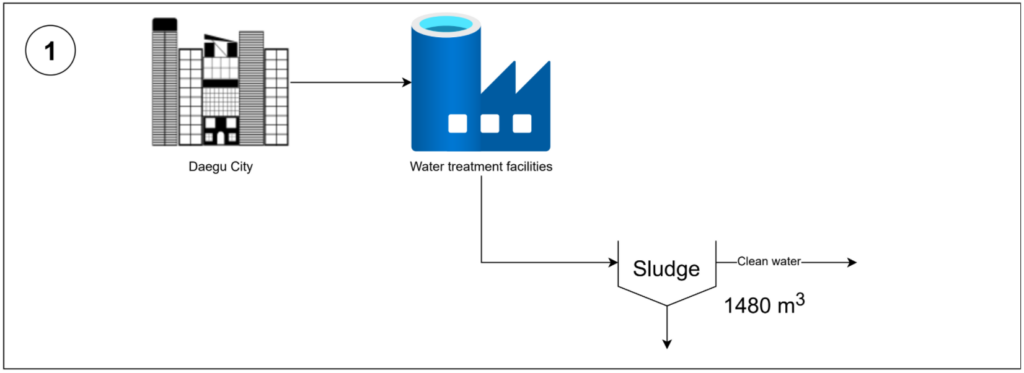

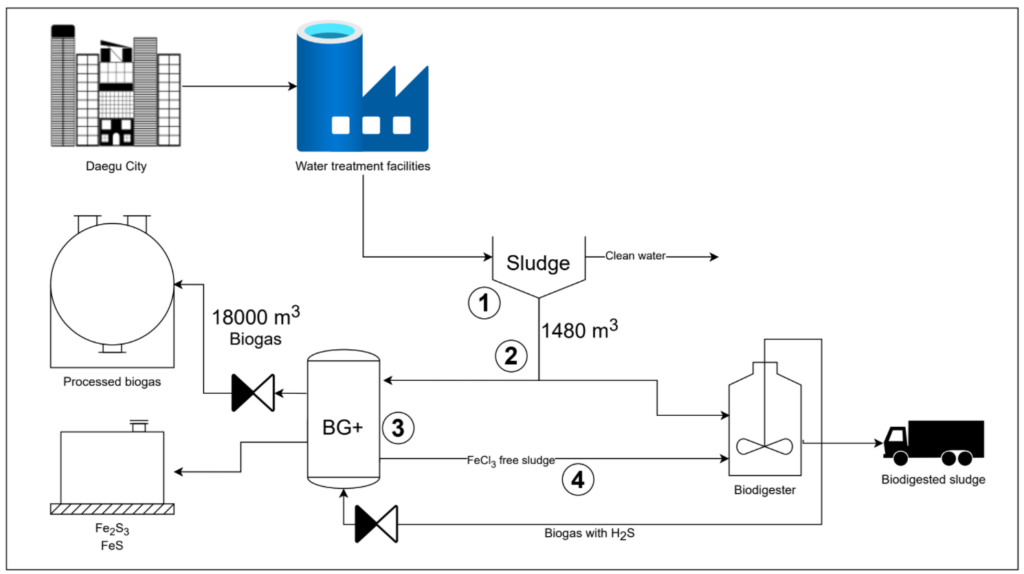

Daegu is the fourth biggest city in South Korea with over 2.5 million inhabitants. The city needs to find new uses for the sludge recovered from Wastewater Treatment Plants, and improve their treatment methods; with the final objective of becoming a Net Zero city. With this in mind, we felt the urge to come up with the optimal solution to this problem, taking a holistic approach.

After looking at the problem and brainstorming possible solutions, we came up with a solution that consists of 4 stages, called “BG+”. With this project, the Wastewater Treatment Plant will improve the efficiency of the sludge disposal process.

Introduction to the BG+ project

You may be wondering, what is BG+? Let us break it down for you.

During the first stage, the residual sludge from the Wastewater Treatment Plant enters the process with a volumetric flow of approximately 1,480 m3.

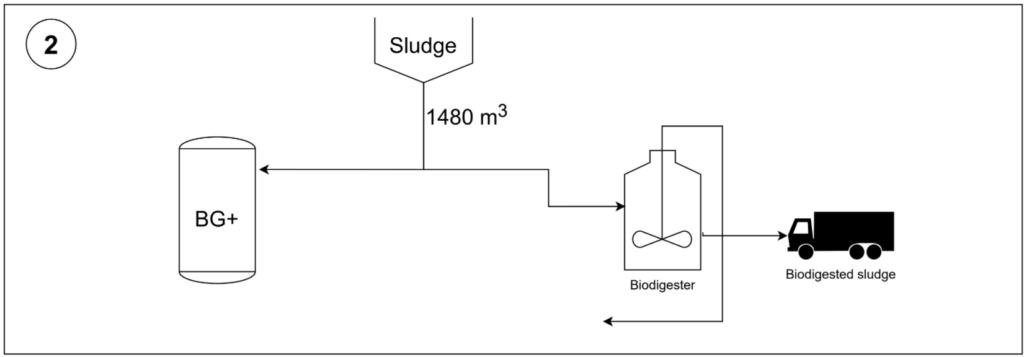

On stage two, the received sludge is divided into two equal parts. The first part, as in the original process, travels directly to the biodigester, where the anaerobic process takes place. While some of the sludge is used for biogas production, the rest travels to the BG+ absorption column improving the efficiency of the process.

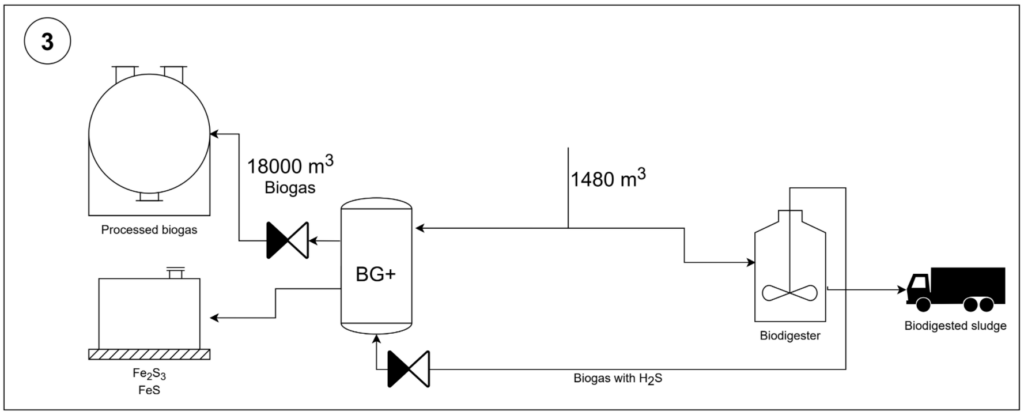

For stage three, a pipe containing Hydrogen Sulfide (H2S) produced in the Biodigestor enters the BG+ as a counterflow stream against the sludge, which contains Iron Chloride (FeCl3). Through a chemical reaction, the Iron Chloride, which acts as the limitant reactant, is cleansed from the sludge. Furthermore, a significant part of the Hydrogen Sulfide is removed. Additionally, Iron Sulfide I (FeS) and Ferric Sulfide III (Fe2S3) are obtained as by-products of the reaction, and can be commercialized in other industries.

Chemical reactions with FeCl3 for sludge dehydration:

- Fe + S ➝ FeS

- 2Fe3 + S ➝ 2Fe2S3

Finally, during the fourth stage, the Iron Chloride-free sludge leaving the BG+ column goes into the biodigester to be turned into a higher quality biogas, due to its lower Hydrogen Sulfide concentration. The total output of Biogas is calculated at approximately 18,000 m3

What makes BG+ Special

BG+ is a simple absorption column designed to reduce the Hydrogen Sulfide in Biogas while also completely purging the Iron Chloride from the sludge. With this small device installed into the Sludge Treatment facility, we estimate that approximately 26% of the Hydrogen Sulfide can be eliminated from the biogas before entering the desulfurizer, significantly reducing operating costs and the desulfurizer’s workload.

By adopting our process, which can easily be implemented in all of Daegu’s Water Treatment facilities and even around the world, you will not only raise profits and reduce production costs, you will also keep Daegu on track to become a zero-waste city.

INVEST IN A NET ZERO FUTURE, INVEST IN BG+